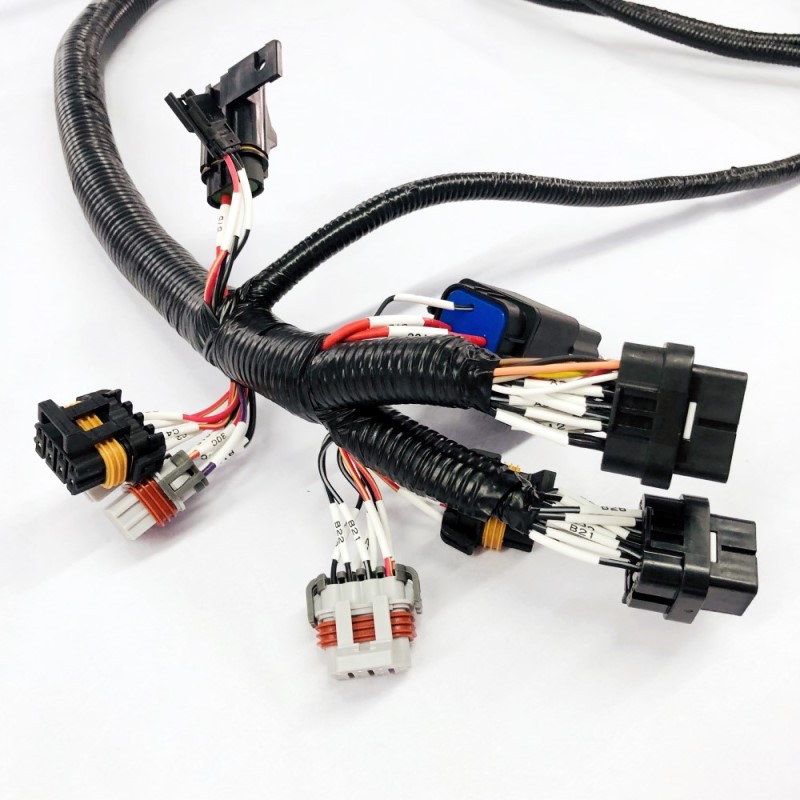

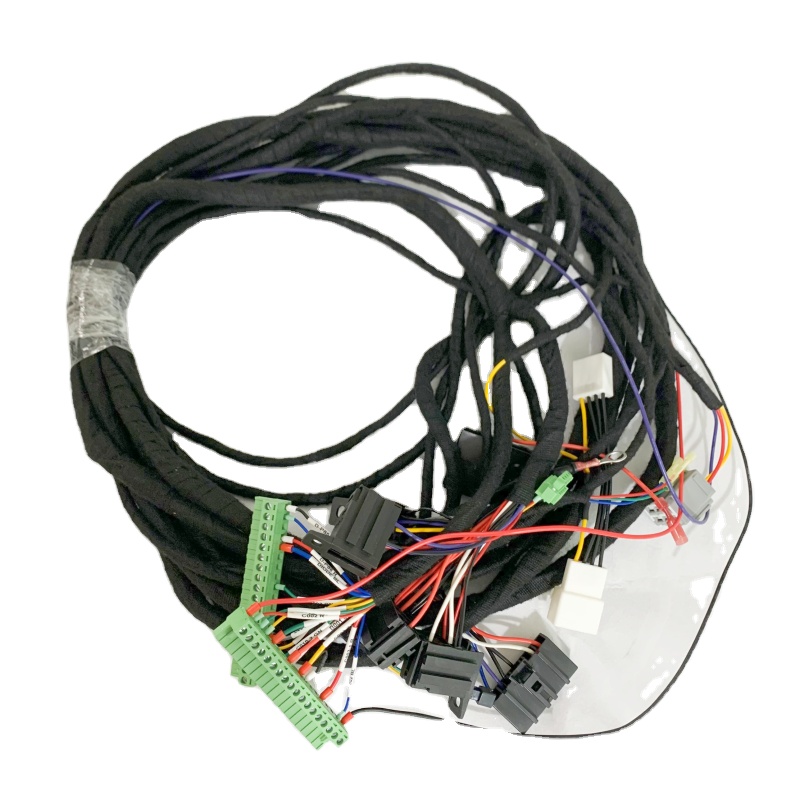

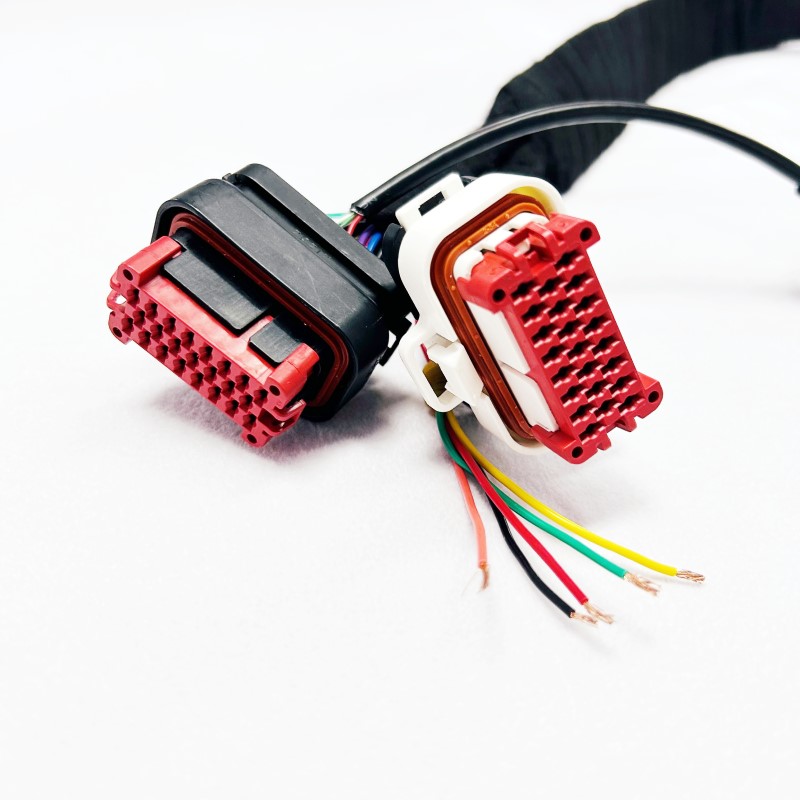

As a leading custom motorcycle wiring harness manufacturer, we have our Meticulous Control at Every Step.

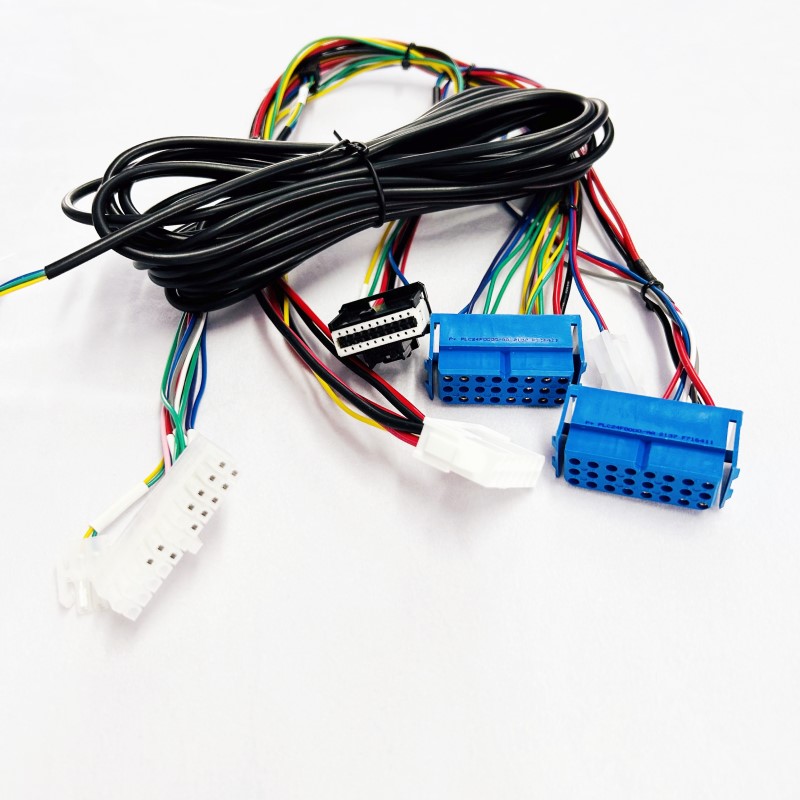

Incoming materials: All raw materials undergo strict quality control to ensure 100% correct.

Production Phase:

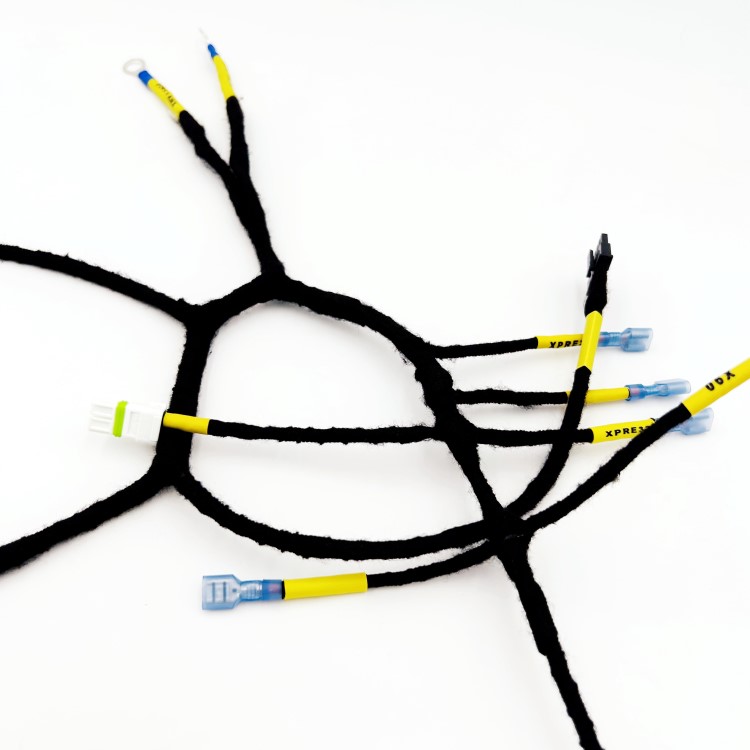

1. Automated wire cutting and stripping machines ensure length accuracy on the custom motorcycle wiring harness.

2. Precision crimping tools control the crimping force error.

3. Manual assembly, high-definition magnifying equipment eliminate missing connections or wrong connections.

Rigorous testing: all custom motorcycle wiring harness are 100% tested before dispatch.

Practical Value: Delivering Long-Term Benefits to Customers

Precise custom motorcycle wiring harness manufacturing cuts failures from poor contact or insulation issues, directly lowering customer maintenance costs and unplanned downtime while boosting operational efficiency.