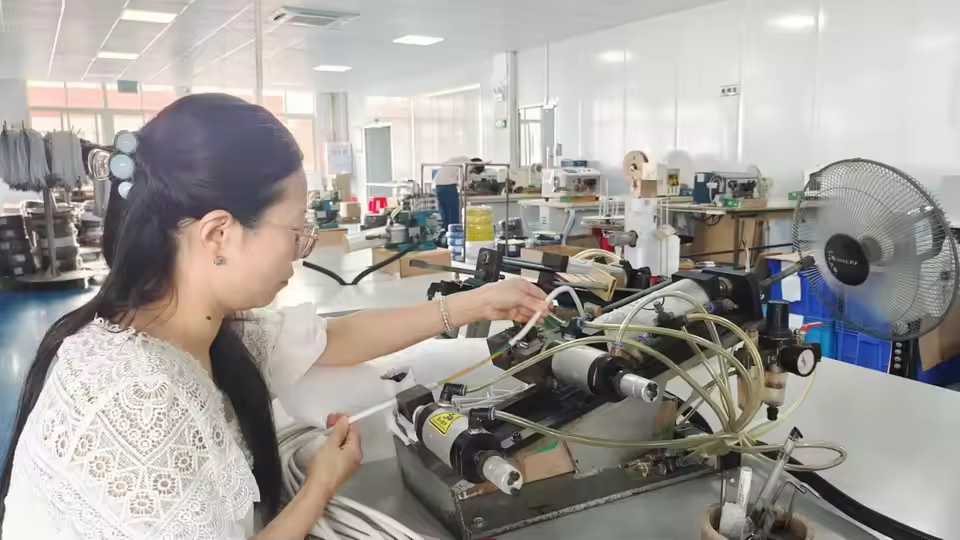

With over 20 years of specialized OEM & ODM automotive cable harness manufacturing experience, we have established ourselves as a trusted partner in the global automotive industry. Our state-of-the-art manufacturing facility spans 5,200 square meters, equipped with high-precision equipment, automated production lines, and advanced testing equipment—all dedicated to delivering premium automotive cable harness solutions.

We hold a comprehensive portfolio of international certifications, including UL, cUL, RoHS, ISO9001, and IATF 16949, which underscores our unwavering commitment to quality, environmental compliance, and automotive industry standards. To ensure zero defects in every shipment, we implement a 100% production self-inspection process, covering raw material verification, in-process quality control, and final product testing.

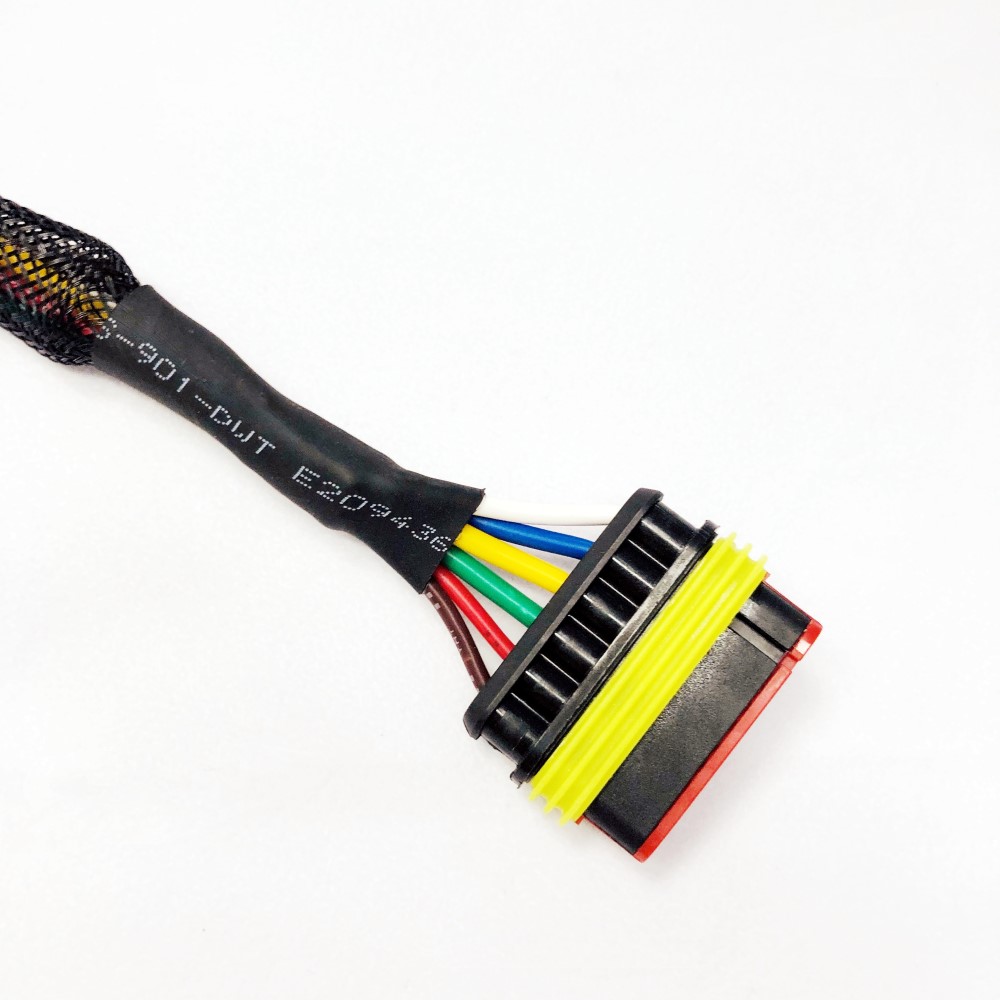

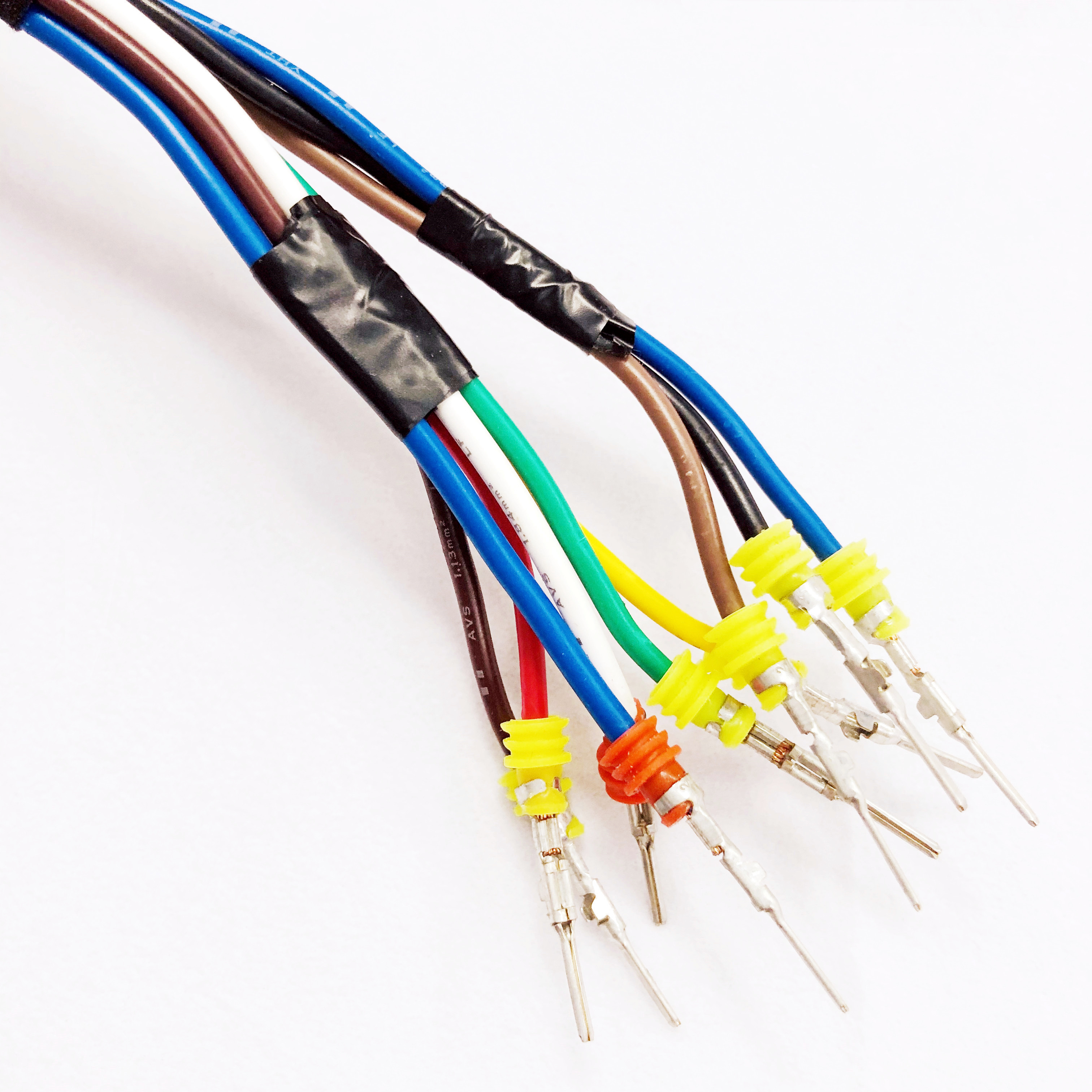

Backed by a team of experienced R&D engineers and technical professionals with deep expertise in automotive electronics, we specialize in customizing automotive cable harness solutions tailored to the unique needs of automotive manufacturers. Our capabilities span the entire lifecycle of automotive cable harness: from collaborative design, mold development, precision manufacturing (including terminal crimping, wire cutting, and automotive cable harness assembly), rigorous inspection, to on-time finished product shipment.

As a one-stop automotive cable harness supplier, we seamlessly integrate design, production, and logistics to streamline our clients’ supply chains, reduce lead times, and lower overall costs. Whether for passenger cars, commercial vehicles, electric vehicles (EVs), or hybrid models, our automotive cable harness is engineered to withstand harsh automotive environments while ensuring reliable electrical connectivity—supporting our clients’ pursuit of performance, safety, and sustainability in the automotive sector.

Specification

| Type | automotive cable harness |

| Conductor | 99.99% oxygen-free copper, Excellent electrical conductivity, extremely low electrical resistivity, and good stability |

| Wire Specification | GXL Wires |

| Quality Management System | ISO 9001:2015; IATF 16949: 2016 |

| Quality Control: | Ensure the correct materials are used and production is carried out strictly in accordance with the drawings. 100% testing and inspected. |

| Connector | Original or alternative |

| Insulation & Jacket | PVC material, excellent abrasion, tensile, corrosion, water, flame-retardant, and oil resistance. |

| Application | Automotive industry |