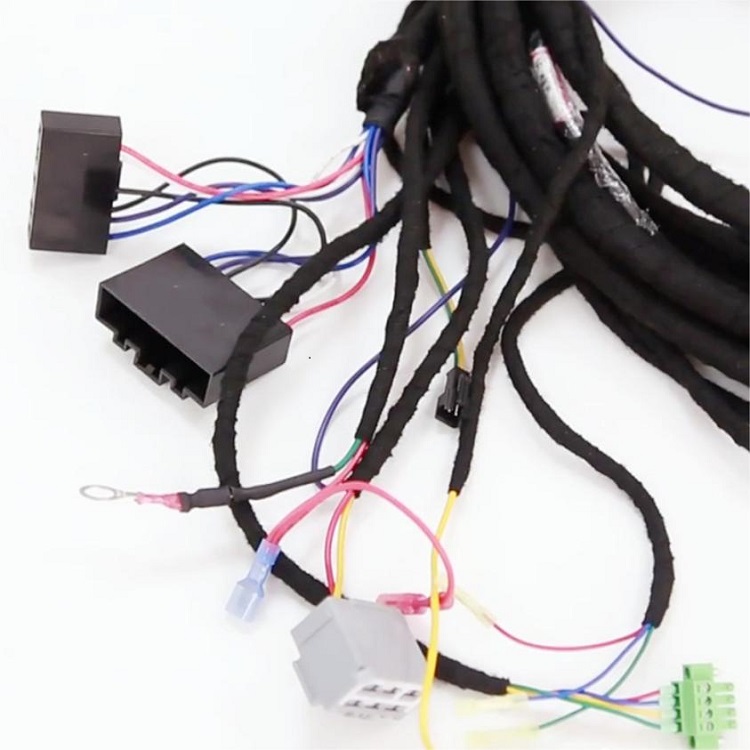

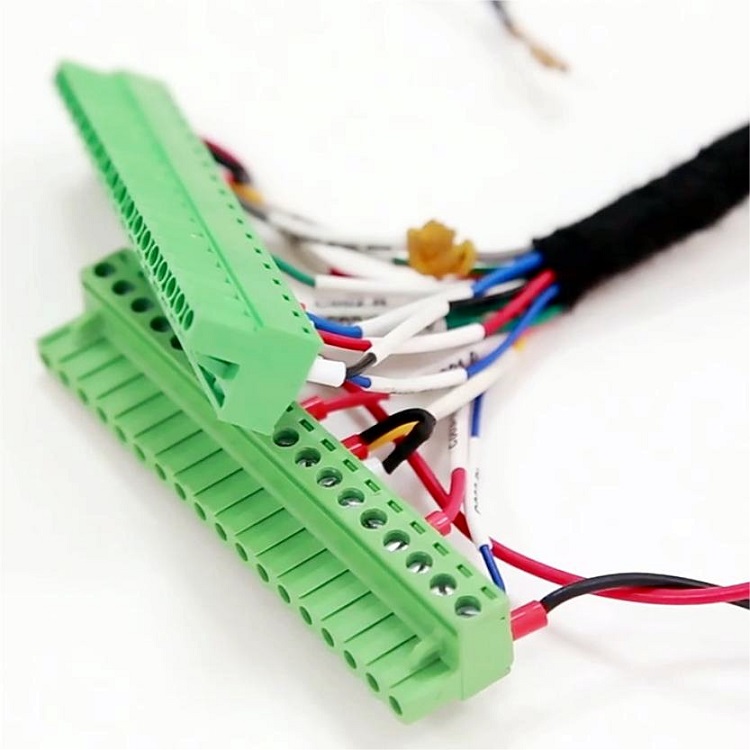

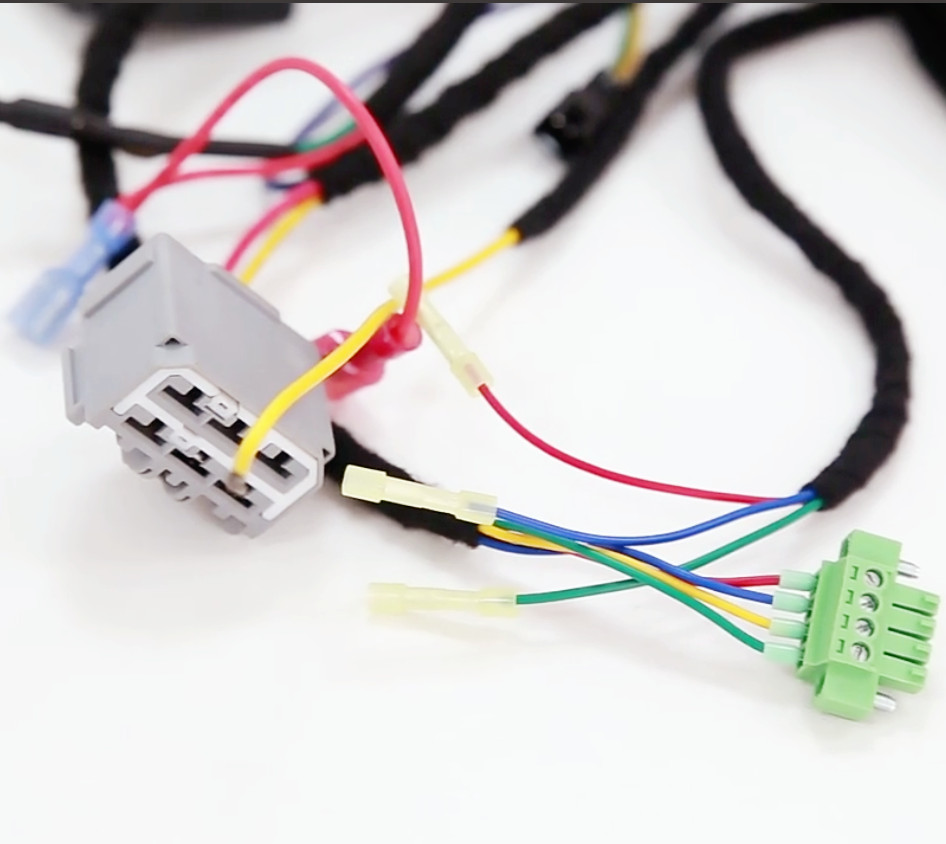

Our factory manufacture customized automotive wiring harness based on customers' drawings and required BOMs. If customers don't have the necessary files, we can also duplicate their samples, and provide customized solutions for all your automotive wiring harness needs, with competitive pricing for products of comparable quality.

To guarantee the high quality of automotive wiring harness, our factory is equipped with cutting-edge technology and production equipment.

We strive to provide excellent automotive wiring harness products and customized services.

We continuously optimize our manufacturing processes to deliver top-quality automotive wiring harness, meanwhile, save costs.

1. IQC Raw materials Inspection: To ensure the quality of raw materials for the automotive wiring harness, all incoming materials undergo a two-step inspection process: initial receiving inspection and laboratory testing. Additionally, a final inspection is conducted before materials leave the warehouse, guaranteeing only qualified items enter the production and processing stages.

2. IPQC Production Inspection: Each production line must have QC inspect every process, whether it's a simple or complex automotive wiring harness. The production

process is essential to ensuring product quality: in-process inspections are conducted at each stage to verify compliance with standards, and only semi-finished products

that meet all requirements and specifications are permitted to proceed to the next manufacturing step. All products are 100% & rigorously tested and inspected;

3. FQC Final Product random inspections: Before finished products are shipped, quality control personnel must conduct random inspections, recheck every details to ensure accuracy and deliver high-quality car wiring harness.

| Type | automotive wiring harness |

| Conductor | 99.99% oxygen-free copper, Excellent electrical conductivity, extremely low electrical resistivity, and good stability |

| Wire Specification | FLRY-A、FLRY-B Wires, etc. |

| Quality Management System | ISO 9001:2015; IATF 16949: 2016 |

| Quality Control: | Ensure the correct materials are used and production is carried out strictly in accordance with the drawings. 100% testing and inspected. |

| Cable Protector | Duct tape |

| Connector Brands | Amphenol, Yazaki, Molex, Deutsch, etc |

| Insulation & Jacket | PVC material, excellent abrasion, tensile, corrosion, water, flame-retardant, and oil resistance. |

| Application | Automotive industry |