Our dedication to excellence is woven into every phase of oem motorcycle wiring harness manufacturing.

From sourcing raw materials to conducting final inspections, we implement strict quality control measures with zero tolerance for corners being cut. Each component undergoes multi-level inspections and tests, ranging from assessments of material strength and durability to performance verification.

Precision manufacturing:

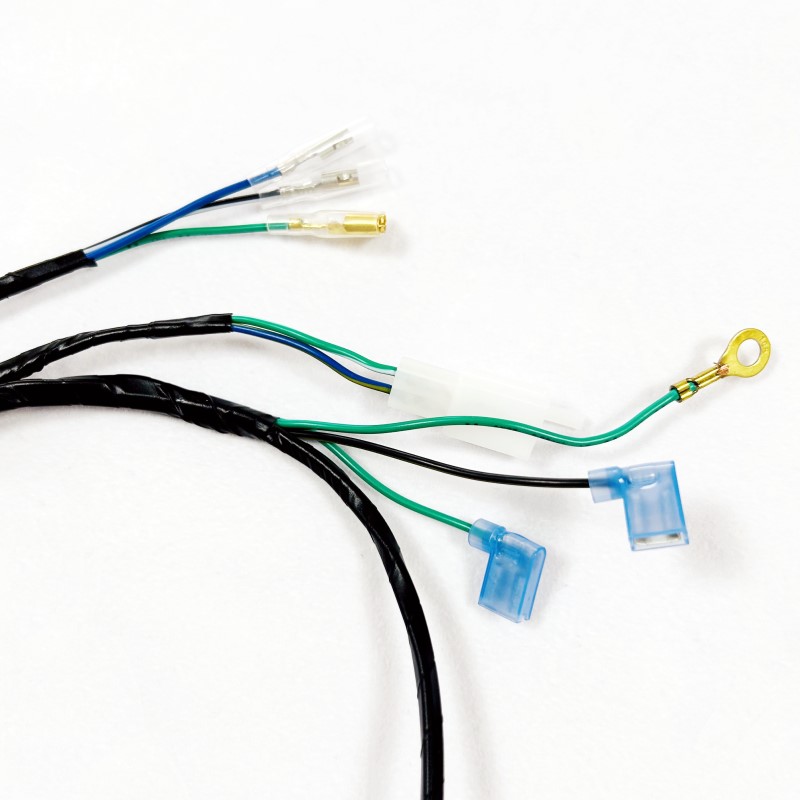

When it comes to assembly, our focus on precision dovetails with efficiency: we streamline workflows to avoid delays without cutting corners, ensuring every component fits seamlessly on the oem motorcycle wiring harness.

Rigorous tesing: Final testing is yet customer-centric. We don’t just validate performance against industry standards; we cross-reference it with the specific use cases our clients outlined, so the end product doesn’t just “work”—it works for them.

On time delivery:

when it's time for delivery, we go beyond meeting deadlines: we coordinate logistics to ensure on-time arrival, with clear documentation.

| Type | OEM motorcycle wiring harness |

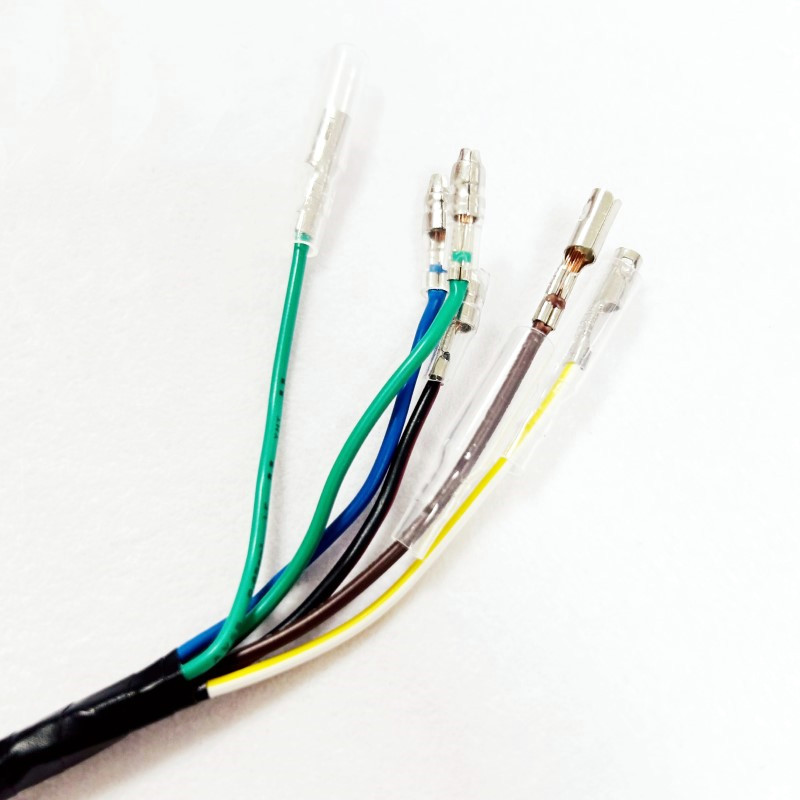

| Conductor | 99.99% oxygen-free copper, highly wear-resistant |

| Wire Specification | UL series standard wires |

| Certificated | ISO 9001:2015; IATF 16949: 2016 |

| Quality Control: | 100% rigorous inspection of materials and finished products testing and inspected. |

| Processing procedures | cutting wires; crimping terminals; assembling, testing |

| Connector Brands | JST, Molex, Yazaki, TE |

| Insulation | Insulated environmentally friendly PVC insulation |

| Application | Motorcycle |