Our commitment to customer satisfaction isn’t just a promise—it’s the foundation of every interaction, guiding us to deliver exceptional driving light wiring harness products and services that spans the entire manufacturing journey.

Our engineering team doesn’t just create driving light wiring harness prototypes; they refine them through iterative feedback, ensuring each mock up aligns with functional needs, budget constraints, and timeline goals.

Uncompromising Quality: Our commitment to excellence is embedded in every stage of driving light wiring harness production.

From raw material sourcing to final inspection, we enforce rigorous quality control protocols that leave no room for shortcuts—each component undergoes multi-layered inspection and testing, from material strength and durability checks to performance validation.

We maintain transparent communication during driving light wiring harness production, providing real-time updates on progress and proactively flagging potential adjustments—because we believe customers deserve visibility, not surprises.

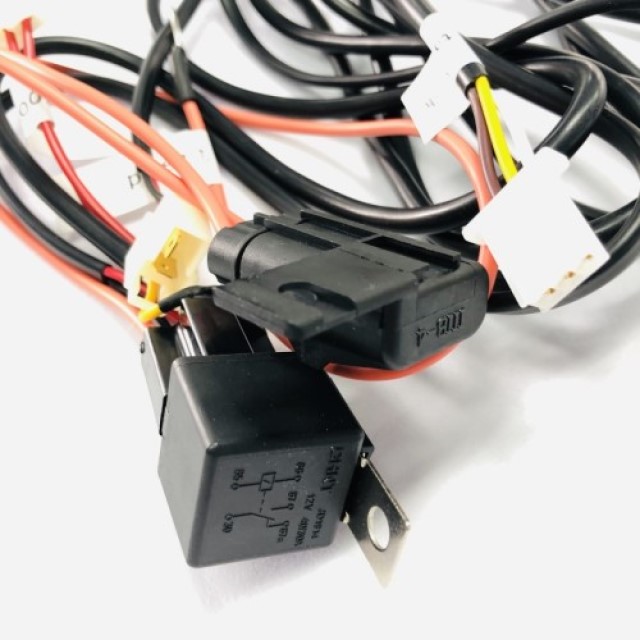

| Product | driving light wiring harness |

| Conductor | 99.99% oxygen-free copper |

| Cable | Double Insulated Cable |

| Voltage | for 12V system only |

| Connectors | 2 Pin Quick Connect; 3 Pin Quick Connect |

| Cable Protector | Protective corrugated tube |

| Plugs | ON/OFF Switch |

| Insulation & Jacket | PVC material, excellent abrasion, tensile, corrosion, water, flame-retardant, and oil resistance. |

| Service | ODM OEM service |