Leveraging our extensive experience accumulated over the years in customized motorcycle wire harness for various enterprises, Yihetai has become a professional manufacturer of motorcycle wire harness. We will concentrate all our resources on ensuring long-term stable development and long-term steady partnership with our customers.

Every stage, from beginning to delivery, is always rooted in a single goal: to make the motorcycle wire harness manufacturing process of as smooth and reliable as possible. For us, the most important is striving to exceed customers' expectations.

Our dedication to ensuring customer satisfaction is more than just a pledge—it forms the basis of every engagement, steering us to deliver outstanding custom motorcycle wire harness products and services throughout the entire manufacturing process.

Our engineering team doesn’t merely develop prototypes for custom motorcycle wire harness; instead, they refine these prototypes through repeated feedback, making sure each draft meets functional requirements, stays within budget limits, and aligns with timeline objectives.

We keep communication open and clear throughout the production of custom wire harness, offering real-time progress updates and taking the initiative to highlight potential adjustments. After all, we’re firm in the belief that customers are entitled to full visibility, not unexpected issues

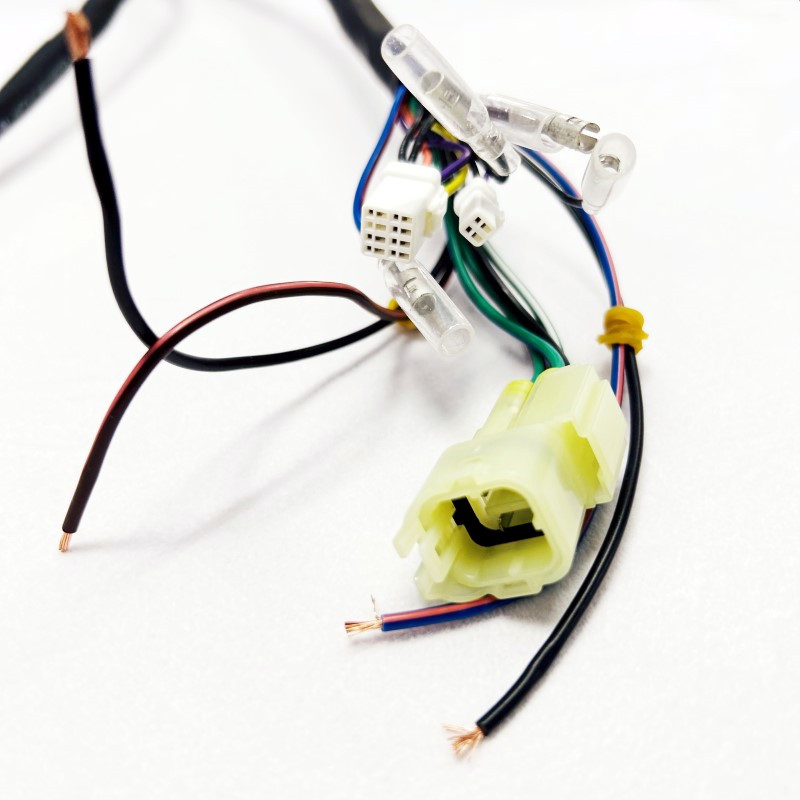

| Type | motorcycle wire harness |

| Conductor | Pure copper conductor, excellent electrical conductivity |

| Certification | ISO 9001:2015 & IATF 16949: 2016 certificated |

| Test | 100% electrical performance tested before delivery. |

| Processing procedures | Wire cutting; terminal crimping; housing assembly; Continuity testing, etc |

| Cable Protector | cloth tape |

| Connectors | Original or alternative |

| Materials | All parts and processing is compliant with ROHS,CCC. |

| Application | motorcycle |