As a trusted engine wire harness supplier, Yihetai is committed to manufacturing premium-quality engine wire harness and delivering comprehensive turnkey solutions tailored to the global automotive sector. Whether clients need standard engine wire harness or complex custom-designed harness assemblies; each engineered to integrate seamlessly with engine powertrain systems, ignition systems, and emission control modules—we adhere to an uncompromising quality inspection process with zero tolerance for defects.

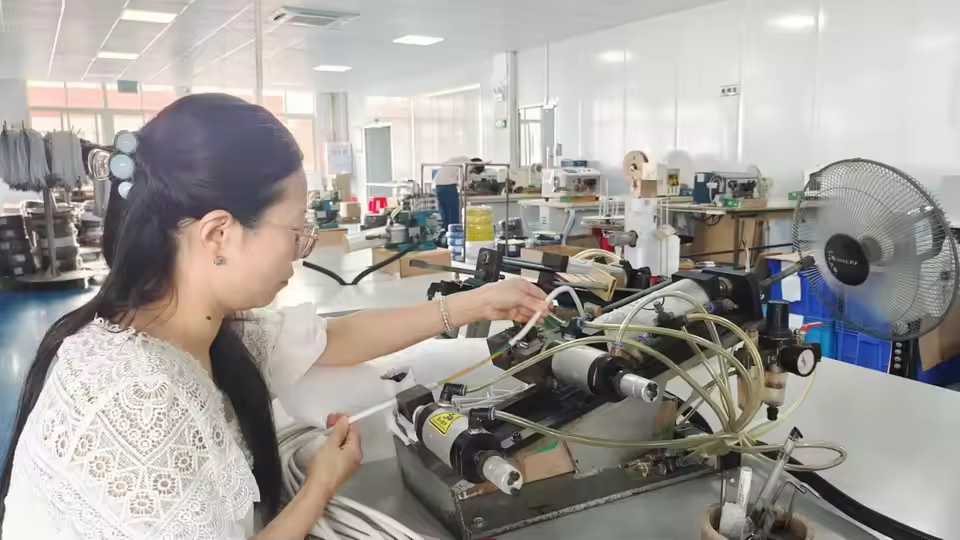

From the arrival of raw materials—including wires, connectors, and other accessories—at our facility, to the production of semi-finished components and final assembly of finished engine wire harness, we implement 100% quality checks at every critical stage. Supported by our IATF 16949 and ISO 9001 certifications, this stringent quality control system ensures that every engine wire harness we supply meets the highest standards of reliability, durability, and performance.

What distinguishes us as a leading engine wire harness supplier is our end-to-end service capability: we seamlessly integrate R&D, custom solutions. Precision manufacturing, rigorous testing, and on-time logistics. Our team of seasoned engineers and technical professionals—with deep expertise in engine wire harness industry, collaborates closely with clients to understand their unique engine platform requirements, delivering not just high-quality engine wire harness products but also technical support, mold development, and after-sales service—truly embodying the value of a one-stop turnkey solution provider for engine wire harness.

For automotive manufacturers and Tier-1 suppliers worldwide, Yihetai stands as a reliable partner that prioritizes quality, flexibility, and customer satisfaction in engine wire harness supply. By leveraging decades of expertise in automotive engine wire harness production and a customer-centric approach, we consistently deliver solutions that optimize our clients’ supply chains, shorten lead times, and support their pursuit of excellence in engine performance, fuel efficiency, emission compliance, and overall vehicle safety and sustainability.

| Product | engine wire harness |

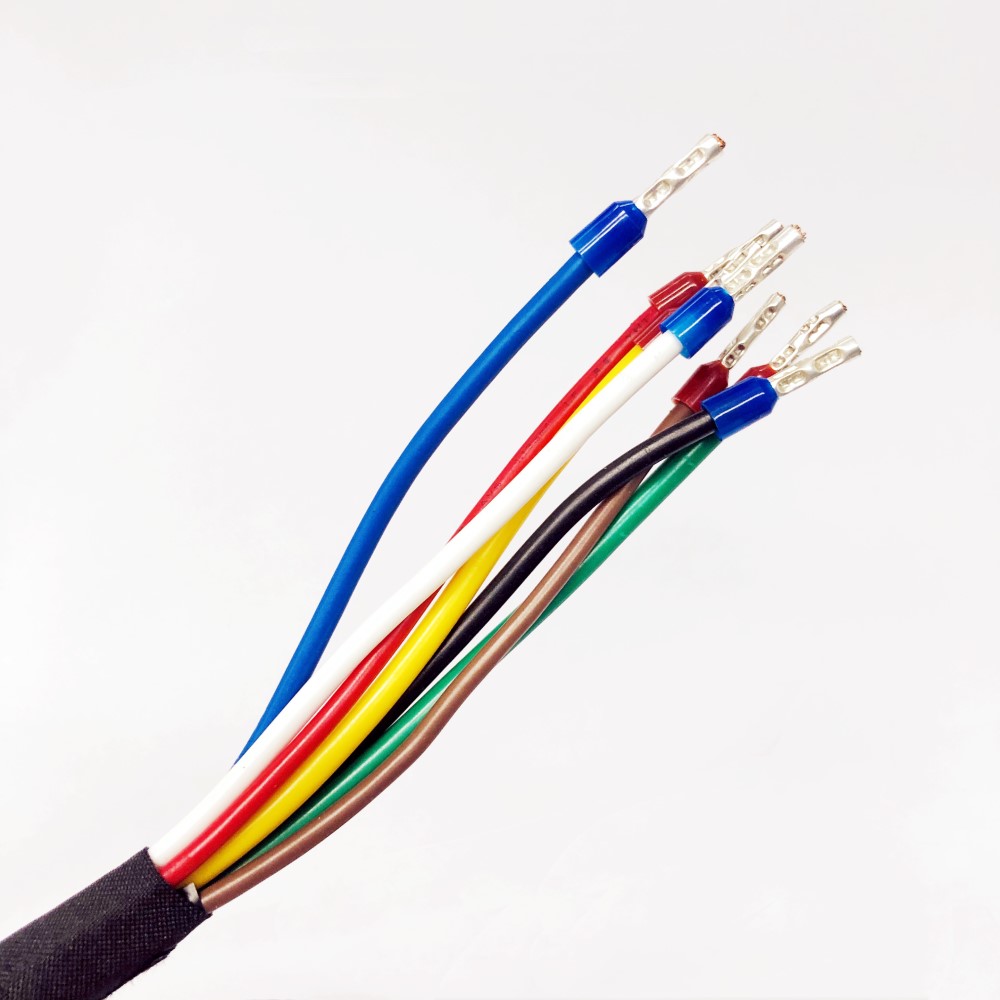

| Conductor | 99.99% oxygen-free copper, Excellent electrical conductivity, extremely low electrical resistivity, and good stability |

| Wire Specification | GXL Wires |

| Quality Management System | ISO 9001:2015; IATF 16949: 2016 |

| Quality Control: | Ensure the correct materials are used and production is carried out strictly in accordance with the drawings. 100% testing and inspected. |

| Cable Protector | Corrugated Tube |

| Connector | Original or alternative |

| Insulation & Jacket | PVC material, excellent abrasion, tensile, corrosion, water, flame-retardant, and oil resistance. |

| Application | Car engine |