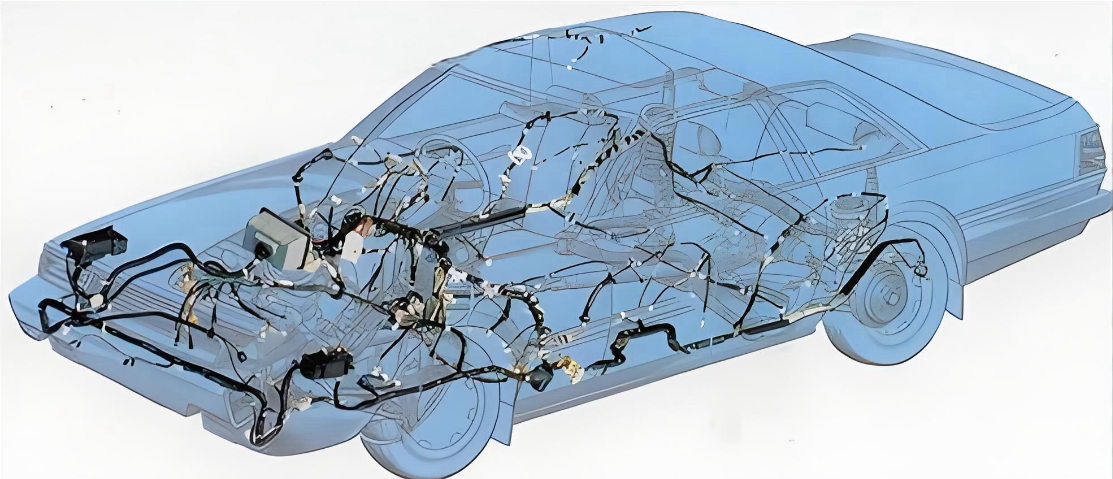

In the age of intelligent vehicles and global electrification, the humble automotive wiring harness has quietly become one of the most critical components in modern mobility. Beneath every dashboard, running through every chassis, and linking every electronic module, electrical pathways form the nervous system of a car. Without them, even the most advanced vehicle would remain a silent shell.

As automakers shift toward smarter, safer, and cleaner transportation, demand for electrical wiring harnesses automotive solutions is soaring. Today’s vehicles carry far more sensors, chips, and communication modules than ever before—meaning a modern vehicle wire harness must not only power essential functions but also support ADAS, infotainment, connectivity, and EV power management. This complex evolution has transformed wire harnesses from simple bundles into engineered systems that require precision, traceability, and global-standard reliability.

A Sector Defined by Precision and Consistency

The global market for car wire harness assemblies has expanded rapidly, driven by the rise of EVs and the tightening of safety regulations. Nowhere is this transformation more evident than in China’s manufacturing landscape, where companies with strong R&D capabilities are setting new industry benchmarks.

Among these innovators, Yihetai stands out as a trusted supplier of customized solutions. As an officially certified High-Tech Enterprise in Xiamen, Yihetai holds both the ISO 9001:2015 and IATF 16949:2016 certifications—international hallmarks of stability, technical rigor, and quality control. Over the past two decades, Yihetai has carefully refined a full-industry-chain ecosystem that covers every step from raw material selection to custom engineering and fast global delivery.

Unlike traditional suppliers, Yihetai integrates R&D, production, and sales into one seamless loop. This allows the company to meet the fast-changing requirements of car electrical harness applications—from EV battery systems and intelligent cockpit wiring to power-train cabling and high-temperature engine components. Their engineering model focuses on durability, signal integrity, modularization, and compliance with ever-stricter automotive standards.

Industry Analysis: Key Parameters Shaping the Automotive Harness Market

| Category | Industry Insight | Market Impact |

|---|---|---|

| Vehicle Electrification | EVs require 2–3× more wiring | Surge in automotive wiring harness complexity |

| Safety Requirements | ADAS & airbag systems demand stable circuits | Higher standards for electrical wiring harnesses automotive suppliers |

| Lightweighting | Aluminum wires replace copper in select systems | Weight reduction for vehicle wire harness assemblies |

| Thermal Performance | Engines & batteries produce high temperatures | Heat-resistant car wire harness designs |

| Connectivity Expansion | Smart cockpits & 5G modules | Growth of data-grade car electrical harness solutions |

These parameters reflect how deeply embedded harness engineering has become in automotive innovation. Every upgrade in vehicle intelligence sets off a chain reaction of new wiring requirements—more shielding, tighter tolerances, faster data speeds, higher safety coefficients, and greater customization.

Why the Automotive Wiring Harness Matters More Than Ever

A modern automotive wiring harness is far more than a cable assembly. It is a strategic component that determines how efficiently a vehicle communicates, reacts, and performs. Inside an EV, the electrical wiring harnesses automotive framework governs everything from charging control to battery monitoring. In gasoline vehicles, the vehicle wire harness supports fuel management, lighting, cooling, and ignition.

Yihetai’s two decades of technical depth allow the company to build tailored car wire harness systems that match the unique demands of global OEMs and specialized automotive equipment manufacturers. Their car electrical harness solutions emphasize reliability under vibration, moisture, voltage spikes, and extreme temperatures—conditions that define real-world automotive performance.

Frequently Asked Questions (FAQ)

1. What exactly is an automotive wiring harness?

It is a structured assembly of wires, terminals, and connectors designed to transmit power and data throughout the vehicle. A modern automotive wiring harness integrates dozens of circuits into one compact, protected network.

2. Why are electrical wiring harnesses automotive systems so complex today?

Because vehicles now rely heavily on electronic control units, sensors, and communication modules. This increases the number of circuits and raises performance requirements.

3. How is a vehicle wire harness tested?

Tests include voltage endurance, pull force testing, temperature shock, salt spray resistance, and 100% continuity testing. These ensure the vehicle wire harness performs under all road conditions.

4. What industries benefit from car wire harness suppliers?

Automobiles, EVs, motorcycles, heavy machinery, robotics, and agricultural equipment all rely on advanced car wire harness assemblies.

5. Does Yihetai support custom car electrical harness designs?

Yes. Yihetai specializes in custom engineering and provides turnkey car electrical harness solutions tailored to global OEM standards.

Conclusion: Wiring the Next Decade of Automotive Innovation

As the global market moves toward smarter and electrified mobility, the importance of the automotive wiring harness will only continue to grow. Companies that master precision engineering and full-chain traceability—like Yihetai—are shaping the future of how vehicles communicate, power up, and remain safe on the road.

Call to Action

If you’re seeking a trusted partner capable of delivering high-precision electrical wiring harnesses automotive solutions backed by more than 20 years of expertise, Yihetai welcomes global collaboration. Whether you need a high-density vehicle wire harness, a modular EV car wire harness, or a fully customized car electrical harness design, Yihetai provides reliable engineering that meets international standards and accelerates product development.