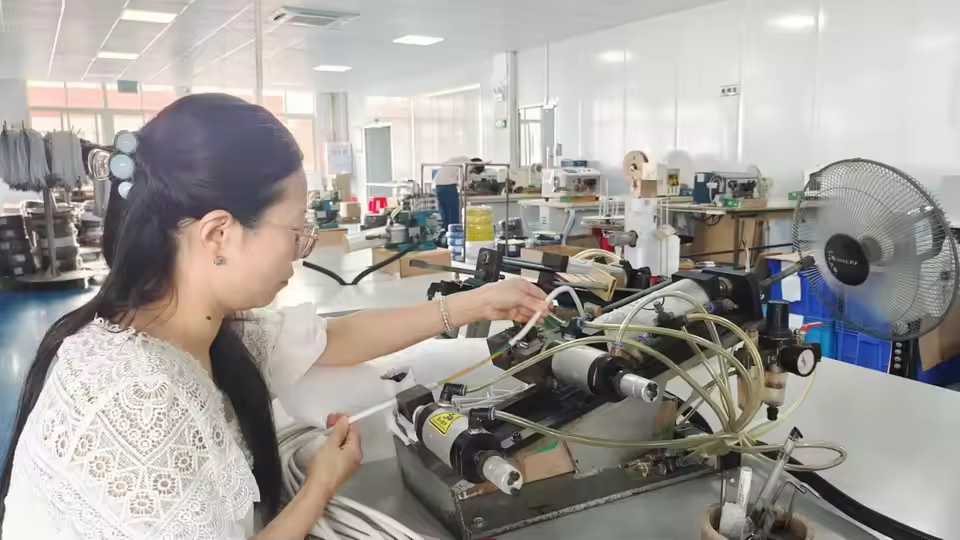

Boasting over two decades of specialized OEM & ODM experience in automotive cable assembly manufacturing, Yihetai has emerged as a trusted partner within the global automotive industry. Our cutting-edge production facility spans 5,200 square meters, outfitted with high-precision crimping machines, automated cable routing systems, and advanced assembly testing stations—all engineered to deliver top-tier automotive cable assembly solutions that meet the rigorous mechanical, electrical, and environmental demands of modern vehicles.

We hold an extensive range of international certifications, including UL, cUL, RoHS, ISO9001, and IATF 16949, which serve as a testament to our unwavering commitment to quality excellence, environmental compliance, and adherence to stringent automotive cable assembly industry standards. To guarantee zero-defect shipments, we implement a 100% self-inspection protocol throughout the automotive cable assembly process, encompassing raw material validation, in-line quality control, and final product testing.

Supported by a team of seasoned R&D engineers and technical experts, we specialize in developing customized automotive cable assembly solutions tailored to the unique requirements of automotive manufacturers. Our capabilities span the entire product lifecycle of automotive cable assemblies: from collaborative design and precision mold development, to high-volume precision assembly, rigorous performance testing, and on-time delivery of finished assemblies.

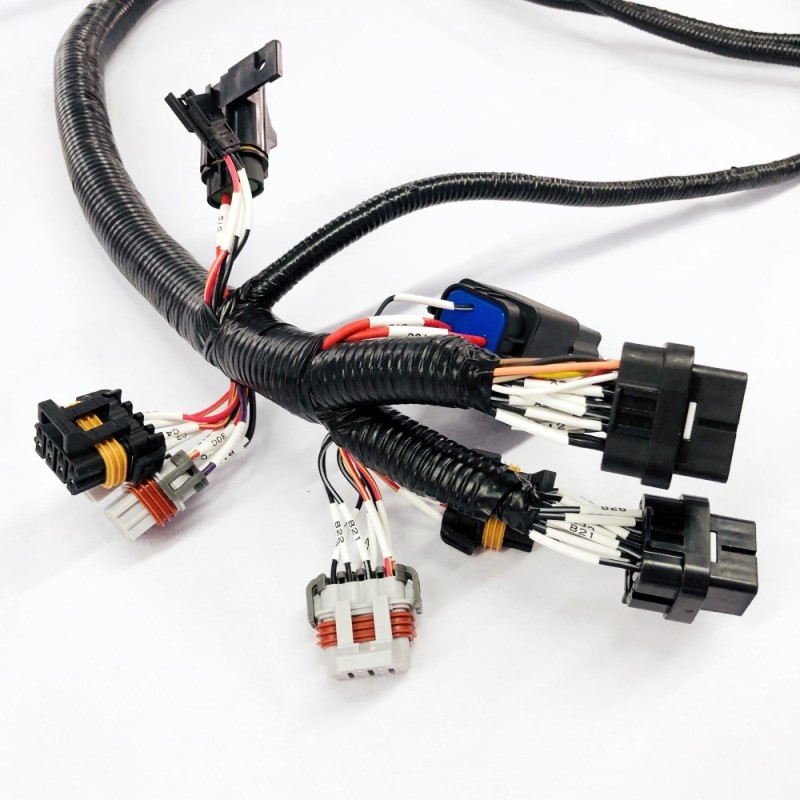

As a one-stop automotive cable assembly supplier, we seamlessly integrate solutions, production, and logistics services to optimize our clients’ supply chains, shorten lead times, and reduce overall costs. Whether for passenger vehicles, commercial vehicles, electric vehicles, or hybrid models, our automotive cable assembly are engineered to endure harsh automotive operating environments. From powertrain control systems and infotainment modules to safety-critical components, our automotive cable assembly deliver consistent performance, empowering our clients to pursue excellence in vehicle performance, safety, and sustainability within the automotive sector.

| Product | automotive cable assembly |

| Conductor | 99.99% oxygen-free copper, Excellent electrical conductivity, extremely low electrical resistivity, and good stability |

| Wire Specification | GXL Wires |

| Quality Management System | ISO 9001:2015; IATF 16949: 2016 |

| Quality Control: | Ensure the correct materials are used and production is carried out strictly in accordance with the drawings. 100% testing and inspected. |

| Cable Protector | Electrical tape |

| Connector | Original or alternative |

| Insulation & Jacket | PVC material, excellent abrasion, tensile, corrosion, water, flame-retardant, and oil resistance. |

| Application | Automotive industry |