As the global vehicle parc continues to age and diversify, demand for reliable aftermarket electrical solutions is growing at an unprecedented pace. From large automotive parts distributors to cross-border eCommerce platforms and international repair chains, buyers are seeking stable wholesale suppliers that can deliver broad vehicle coverage, consistent quality, and fast fulfillment. In this environment, China has become a critical sourcing hub for aftermarket wiring systems, particularly Bundles automotive cable harness solutions designed for replacement and retrofit applications.

Yihetai, a Xiamen-based High-Tech Enterprise with ISO9001:2015 and IATF 16949:2016 certifications, has positioned itself as a dependable wholesale partner for global aftermarket buyers. Leveraging over two decades of manufacturing experience, the company supports customers across North America, Europe, and Asia with cost-effective, standards-compliant harness assemblies tailored for wholesale distribution.

Aftermarket Demand Is Reshaping the Harness Supply Chain

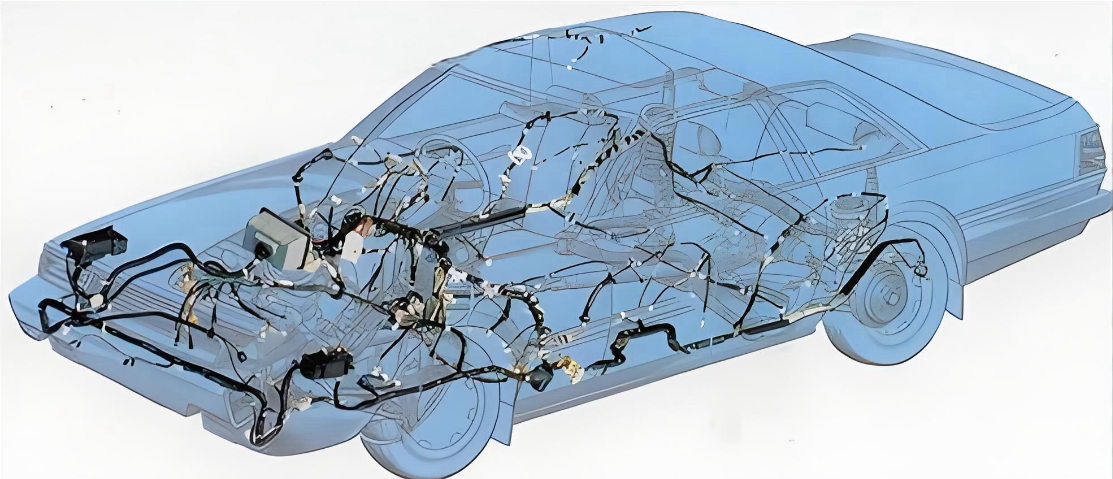

Unlike OEM production, the aftermarket sector prioritizes availability, compatibility, and pricing flexibility. Distributors and repair networks need fast-moving SKUs that fit a wide range of models without compromising electrical safety. This has driven strong demand for modular wire harness automotive products that can serve multiple replacement scenarios.

Key market drivers include:

Aging vehicle populations in the US and EU

Growth of large-scale auto parts eCommerce platforms

Increased electrical complexity in modern vehicles

Expansion of vehicle modification and retrofit markets

To meet these needs, suppliers must maintain comprehensive catalogs of automotive harness wire assemblies covering Japanese, European, Korean, and American vehicle platforms.

Yihetai’s Wholesale Manufacturing Model

Yihetai operates on a full-industry-chain model, ensuring tight control from raw material sourcing to final shipment. This structure enables stable output and predictable lead times—critical factors for wholesalers and large aftermarket buyers sourcing Bundles automotive cable harness products at scale.

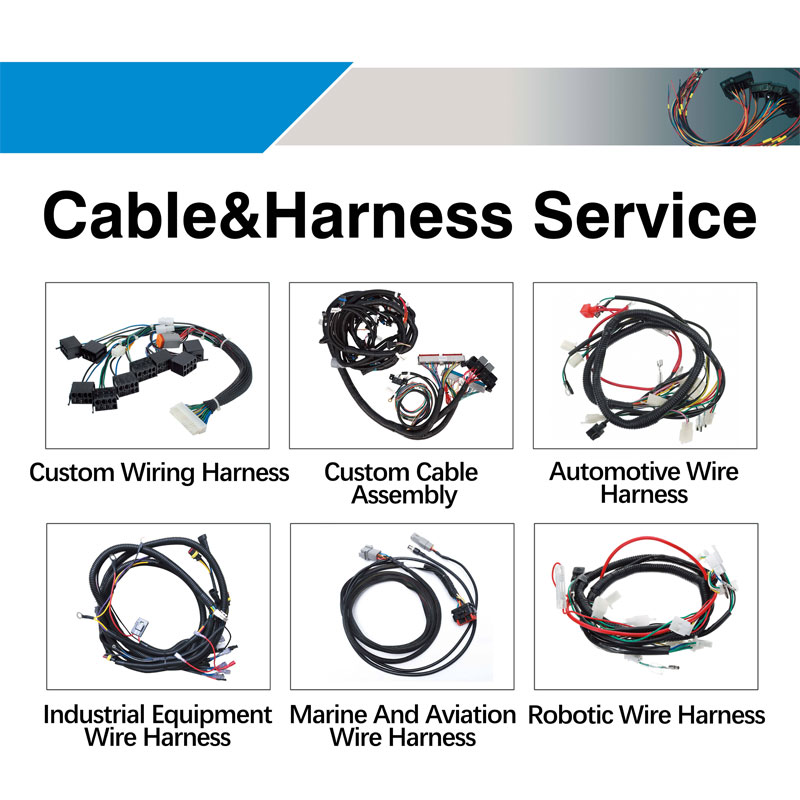

Broad Product Coverage

Yihetai’s product matrix includes replacement harnesses for lighting systems, engine compartments, dashboards, doors, sensors, and auxiliary systems. Each Automotive Cable Harness Wire assembly is engineered for plug-and-play compatibility to reduce installation time in workshops.

Flexible MOQ & Inventory Support

Understanding the realities of aftermarket sales, Yihetai offers flexible minimum order quantities. This allows distributors to test new SKUs or expand product lines without excessive inventory pressure, particularly for wire harness automotive replacement kits.

Certified Quality for Global Markets

All products are manufactured under ISO9001 and IATF 16949 systems, with optional compliance to UL, CE, and SAE standards. This ensures that every automotive harness wire meets regulatory and safety expectations across multiple markets.

Industry Comparison: Aftermarket vs OEM Harness Requirements

| Parameter | OEM Vehicle Production | Aftermarket Replacement |

| Volume Pattern | Large batch, fixed models | Multi-SKU, flexible volume |

| Vehicle Coverage | Single platform | Multi-brand, multi-year |

| Lead Time | Long-term planning | Short & responsive |

| MOQ Requirement | High | Low to medium |

| Installation Priority | Assembly line efficiency | Workshop efficiency |

| Customization Level | Platform-specific | Modular & adaptable |

This contrast highlights why aftermarket buyers increasingly favor suppliers with strong Custom Wire Harness capabilities and catalog depth.

Engineering Strength Behind Cost Efficiency

Yihetai’s R&D team, led by engineering managers with more than 20 years of industry experience, plays a central role in balancing cost and performance. By optimizing conductor selection, insulation materials, and connector interfaces, the company delivers Bundles automotive cable harness solutions that maintain durability while remaining price-competitive.

Rapid prototyping allows Yihetai to respond quickly to new aftermarket demand, whether for discontinued models or emerging retrofit trends. This agility is especially valuable for buyers managing large Automotive Cable Harness Wire product portfolios.

Serving a Global Aftermarket Customer Base

Yihetai’s wholesale customers include:

Automotive parts wholesalers

Large auto parts eCommerce sellers

Overseas repair shop chains

Vehicle modification and tuning suppliers

For these clients, sourcing reliable wire harness automotive products is not just about price—it is about consistency, documentation, and long-term supply stability. Yihetai supports this with clear product catalogs, standardized specifications, and a transparent quotation process for Custom Wire Harness projects.

Frequently Asked Questions (FAQ)

Q1: Does Yihetai support aftermarket-specific designs?

Yes. Yihetai specializes in Custom Wire Harness development for aftermarket and replacement use, including adaptations for multiple vehicle generations.

Q2: What vehicle brands are covered?

Products cover mainstream Japanese, European, American, and Korean models, with continuous expansion of automotive harness wire SKUs.

Q3: Are small trial orders accepted?

Flexible MOQs are available for many Bundles automotive cable harness products to support market testing.

Q4: What quality tests are performed?

Each Automotive Cable Harness Wire undergoes continuity, insulation resistance, and mechanical strength testing before shipment.

Q5: Can Yihetai support private labeling or branded packaging?

Yes. OEM and ODM services are available for wire harness automotive wholesale customers.

Clear Sourcing Process for Wholesale Buyers

Yihetai has streamlined its inquiry and ordering workflow to match the needs of high-volume aftermarket buyers:

Share vehicle models or part references

Receive a detailed product list or matching proposal

Confirm specifications and pricing

Approve samples (if required)

Proceed to bulk production or repeat orders

This structured process ensures efficient sourcing of Custom Wire Harness solutions with minimal friction.

Call to Action: Build a Stable Aftermarket Supply Partnership

For wholesalers and automotive service networks, supply reliability is a competitive advantage. Yihetai combines manufacturing scale, certification, and engineering depth to support long-term aftermarket growth with dependable Bundles automotive cable harness products.

Whether you are expanding a product catalog or optimizing replacement inventory, Yihetai offers the technical and commercial foundation needed to compete in today’s aftermarket landscape.

Conclusion

The global automotive aftermarket is evolving toward greater complexity, faster turnover, and higher expectations for quality. In this environment, dependable suppliers of Automotive Cable Harness Wire assemblies play a decisive role in keeping vehicles on the road and customers satisfied.

Yihetai’s full-chain manufacturing model, experienced engineering team, and flexible wholesale strategy make it a trusted China-based partner for distributors, eCommerce sellers, and repair networks worldwide. By delivering consistent automotive harness wire solutions at scale, the company continues to strengthen its position in the global aftermarket supply chain.